Hydration mechanism and properties of low-CO2 cements based on magnesium hydroxycarbonates

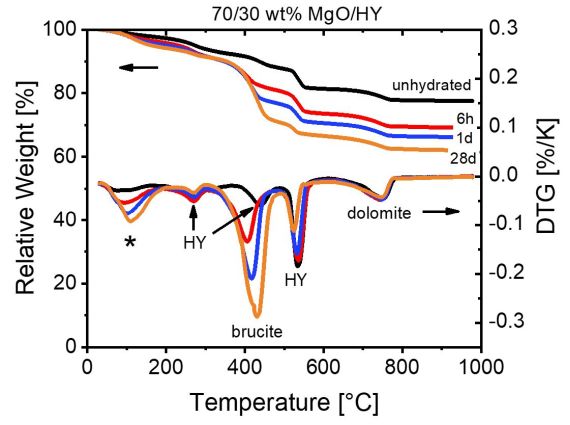

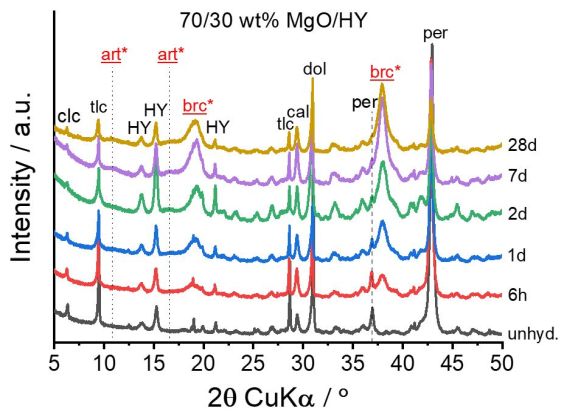

To lower CO2 emissions released from Portland cement manufacture, new cementitious materials (alternative binders), whose production are not as emission-intense as for Portland cement, became an active field of cement research in recent years. The aim of this project is to examine the suitability of MgO/hydromagnesite (Mg5(CO3)4(OH)2·4H2O) blends for construction purposes. These blends can potentially be used in concrete and display the possibility of a reduced CO2 footprint as a consequence of the manufacturing process of MgO. The process involves carbonation of magnesium silicate minerals such as forsterite (Mg2SiO4) or serpentine (Mg3Si2O5(OH)4) and subsequent calcination of the artificially obtained magnesite (MgCO3). The MgO/hydromagnesite binder remains a largely unexplored chemical system, which shall be investigated with chemical-analytical methods and finally be put into action by formulating concrete mix designs. The research is conducted at Empa by the Cement Chemistry and Thermodynamics group.

Project Period

2019 - 2023

Winnefeld, F., Epifania, E., Montagnaro, F., and Gartner, E. M., 2019, "Further studies of the hydration of MgO-hydromagnesite blends", Cement and Concrete Research, 126, 105912

Conference Paper

Winnefeld, F., Epifania, E., Montagnaro, F., and Gartner, E. M., 2019, "Hydration of MgO in the presence of hydromagnesite", Proceedings of the International Conference on Sustainable Materials, Systems and Structures (SMSS 2019) - New Generation of Construction Materials, 20-22 March 2019, Rovinj, Croatia, Rilem Proceedings PRO 128, RILEM Publications S.A.R.L., Paris, France, 363-370

Winnefeld, F., Epifania, E., Montagnaro, F., and Gartner, E. M., 2019, "New insights into the hydration of cementitious materials based on magnesium carbonates", ILCCC 2019, 1st International conference on innovation in low-carbon cement & concrete technology, London, United Kingdom

A. German, F. Winnefeld, P. Lura, Hydratation von MgO/Hydromagnesit-Gemischen, Tagung Bauchemie, 54 (2019) Aachen, Germany, 151-157

German, F. Winnefeld, P. Lura, Hydratation of MgO/HY blends, ICCM, ACI/RILEM International Conference on cementitious materials and alternative binders for sustainable concrete, (2020) Toulouse, France. (accepted, conference postponed due to COVID-19)

-

Share